January has been a slow rather mojo-less sewing month this year. I had all these grand plans, and have felt zero compulsion to sew anything. So I’ve been fixing, mending and twiddling on a few things.

First, I tweaked the bodice of DD2’s Christmas dress (Burda 12/2012 #110). Originally it looked like this, with ponte and lace all eased into a higher-than-designed neckline. It didn’t work, and there was an absurd amount of ease to sew into the neckline. And, because it still wasn’t decent enough, I added a triangular lace insert at the CF. I was not happy with it – it looked so less-than-custom-made, but it had to do for Christmas.

Now, after lowering the CF on the ponte under layer (the bodice is unlined) as far as it would go – and as designed, I might add – and removing the CF lace insert, it looks like this.

Not a big difference, but the fit along the neckline is much better. I’m still getting my head wrapped around fitting DD2 and what looks good on her. Most of my sewing queue over then next couple of months will be for her, so hopefully I will learn a lot!

Then I agreed (with dread in my heart) to redo window valances. I always hate being asked to do things out of my comfort zone, because I hate feeling like I don’t know what I’m doing. I have no pictures of the project, but let me just say that it was an interesting ride. In early December, I met with the client and the interior designer, and confessed that home dec sewing is not in my field of expertise. So the designer measured all the windows, wrote them down for me, and off I went with the valances, her measurements and extra fabric from the client’s storage room. After pulling one of the valances apart, I understood the method of construction, and started in on the project. Everything was neat and tidy and I was pleased with my amateur work. Up went the valances, and the client called me after Christmas to tell me that they were too short for two of her windows. My bad. I didn’t check the math of my measurements with a calculator. And, to top it all off, the designer’s depth measurements were off by 2.5cm, so everything had to be taken apart and re-done so the corner box pleats actually hung at the corners.

And I’ve been BUGGED – BUGGED, I tell you – by the little details of the project. The valances had a centre box pleat, which should have hung in the visual centre of the windows i.e. in the centre of the centre sliding frames. But visual centre did not equal mathematical centre, so the centre pleats hang about 4cm off visual centre. Do you follow me here? And, of course, the designer wanted the centre pleat to hang in the visual centre, not the actual centre. Ugh.

And that bugs me. BUGS ME!! Part of me wants to go back and re-do those damn valances a third time, just so they can all be truly custom-made for those damn windows.

BUT…. and this is a big ‘but’…. I stopped to study a valance in my bedroom which was made a couple of years ago by one of the best drapery guys in the city. He had worked solely off the window measurements the designer had given him, and after carefully looking at all the proportions, I realized that the mathematical centre of that valance was definitely not the visual centre in relation to my bedroom window.

And he is a paid drapery expert. So I’m not kicking myself anymore. C’est la vie, and all that. But I did learn a lesson for the next time someone wants valances made by little ol’ moi. Experience, experience! Best teacher ever.

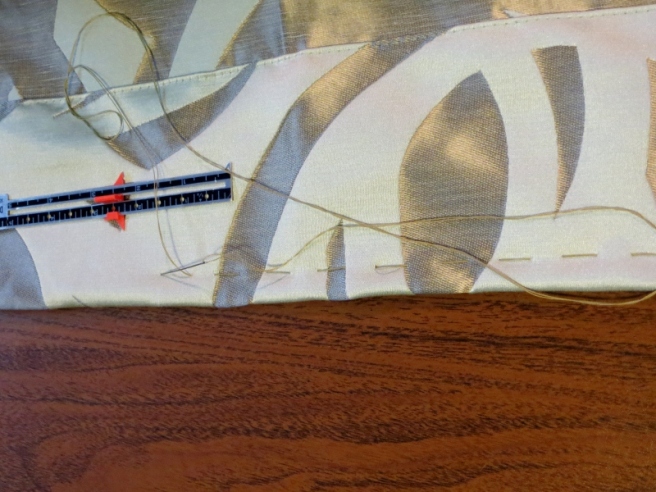

The next project was to give myself a new ironing board cover.

I have no pictures of the old one, but I will tell you that the foam padding had melded to the cotton cover through overuse. I made mine from washed muslin and the leftover cotton batting (from my first attempt to make interlined Roman blinds). It looks clean and the thick new padding is wonderful. I should have done this months ago.

Then I put the waistband ties onto a pair of hip-hop trousers for DD1. I made these last spring, I think, and she grabbed them before I could finish them, and has been wearing them ever since. Yesterday she was walking around the house in them like she’d had some sort of horrible injury in the pelvic region, and I asked her why she was walking so oddly. She said she had to walk like a weirdo so the pants wouldn’t fall down. *headshake* The ties have been hanging on a project board since the trousers were made, so today they finally ended up on my sewing table to be properly finished.

And now I’m working through three projects that were cut late summer:

a safari skirt (Burda 04/2010 #140)

a silk scarf panel top (Burda 07/2012 #118), albeit with different fabric and multiple-gored skirt for DD1 (Burda 06/2013 #132).

and multiple-gored skirt for DD1 (Burda 06/2013 #132). And I had hoped to get myself moving on Jungle January and Chris’s #JeansinJanuary, but I lacked both the conviction and motivation to start in on anything. So I’ve missed both, but I am determined to finish all my UFOs before I begin something new.

And I had hoped to get myself moving on Jungle January and Chris’s #JeansinJanuary, but I lacked both the conviction and motivation to start in on anything. So I’ve missed both, but I am determined to finish all my UFOs before I begin something new.